RESOURCES

HELPFUL LINKS

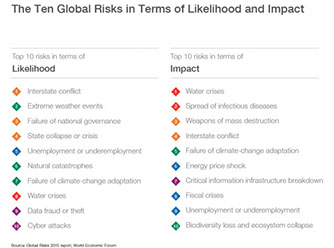

Global Risk Map

Global Risk Landscape

<

>

- TCO Estimator

- Global Risk Map

- Global Risk Zurich – explain economic forum

- Global Risk Landscape 2015 World Economic Forum Info graphics

- Risk Management in the Supply Chain

- 6 Tips for Optimizing Your Distribution Network

- Raytheon's Supplier Relationship Management

- 2016 Global Growth Risks

- How Well Does Your Company Integrate Demand and Supply?

Managing Risk

Risk and sustainability are not mutually exclusive. The linkage between risk and sustainability is gaining traction due to social and environmental impacts and requirements for tighter regulations with more detailed monitoring. Leaders in organizations are recognizing sustainability is more than environmental. In fact, it requires managing all risk for business. Global Supply Chains in the future will need to manage both a greater degree of risk requirements and increased sustainability value.To achieve this, stronger process management and new automation tools will support these demands on company’s supply chain for risk performance and corporate social responsibilities (CSR).

Fixing Weak Links in the Supply Chain

1. Create a vision to predict, prevent and mitigate impact to Supply Chains (SC)

2. Develop contingencies and buffer with options

3. Employ smart technologies4. Look down the SC pipeline to create more robust processes into the suppliers’ supplier

5. Develop cross-functional risk processes and create synergiesMitigating impact to supply and delivery while keeping current with trade regulations and supplier engagement though Supply Chain Risk Management (SCRM).

Building Resilience

Below are points and a link from the World Economic Forum (WEF)

An Important Subject of the Building Resiliency, Offsetting Risk and Gaining Efficiencies and How Do You Balance Those in Today’s Connected World.

Initiative aims to:

- Revisit key risks in the supply chain

- Strengthen the framework for global risk assessment

Build a blueprint for supply chain resilience

- Improve collaboration and transparency across supply chain actors

http://new.livestream.com/accounts/1909571/events/1790729/videos/10021947

Supply chain is a key to competitive advantage in many companies, significantly determines the social, economic and environmental impacts of your company, which in turn influence more and more of your stakeholders and shareholders. Hence a sustainable supply chain strategy representing one of the most important success factors for achieving sustainable development for your company and must exhibit the following characteristics:

- Your supply chain is aligned to the underlying corporate and competitive strategy

- Your supply chain considers demand, supply, and in particular other, wider general conditions

Additional reference link on building supply chain resilience: https://www.youtube.com/watch?v=lxf-uArALCw

Countries that have the most resilient supply chain

Resilience – is about having contingency plans in place – example is having good practices and processes with technology enabling visibility and transparency with what your suppliers’ suppliers are doing. There is a case were multiple first levels of suppliers all deal with one airbag manufacturer in Japan. When the airbag supplier has a problem all automotive suppliers first tier or level have a problem with air bags installed into steering wheel systems.

Japan's manufacturing industry weathered the post-Fukushima crisis pretty well, all things considered, but other countries are less prepared for big disasters report says. By 24/7 Staff

Resilient Supply Chains Require

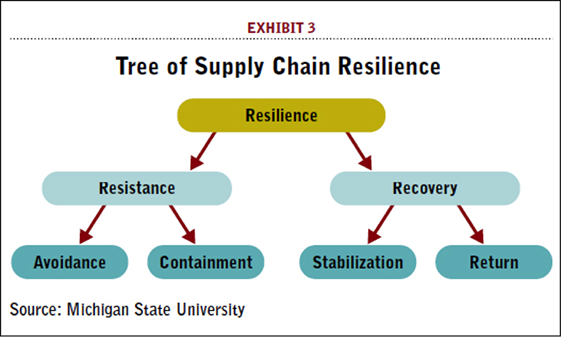

Resilience happens by design and not by accident. The resilient supply chain requires two (2) critical capacities: The capacity for resistance and the capacity for recovery.

1. Resistance defines the supply chain’s ability to delay a disruption and reduce the impact once the disruption occurs.

2. Recovery, defines the supply chain’s ability to recover from a disruption.

The remainder of the article identifies (link below) and discusses the trade offs between these two resilience capacities, how each responds to issues of supply chain uncertainty and risk, and investments that firms can make to enhance supply chain resilience capabilities. The conclusion: Resilience is a capability that must fit the specific needs of each firm.

http://www.supplychain247.com/article/understanding_supply_chain_resilience

Supply Chain Resilience Defined

Supply chain resilience is “the ability of a supply chain to both resist disruptions and recover operational capability after disruptions occur.“ As mentioned above, viewed from this perspective, resilience consists of two critical but complementary system components: the capacity for resistance and the capacity for recovery. Let’s look more closely at those elements:

- Resistance capacity is the ability of a system to minimize the impact of a disruption by evading it entirely (avoidance) or by minimizing the time between disruption onset and the start of recovery from that disruption (containment).

- Recovery capacity is the ability of a system to return to functionality once a disruption has occurred. The process of system recovery is characterized by a (hopefully brief) stabilization phase after which a return to a steady state of performance can be pursued. The final achieved steady-state performance may or may not reacquire original performance levels, and is dependent on many disruption and competitor factors.

Resilience Index

FM Global Resilience Index - Understanding the Index

- http://www.fmglobal.com/page.aspx?id=00010004

- http://www.wsj.com/articles/when-manufacturing-means-building-supply-chain-resilience-1445443202

Black Swans and the Risks in Supply Chains

Yossi Sheffi of Massachusetts Institute of Technology (MIT) writes that building business resilience into supply chains means preparing for the unimaginable”

Supply Chain Disruption is a link from Thomas Goldsby of Ohio State

Harry T. Mangurian, Jr. Foundation Professor in Business at Fisher College of Business

Some great new work out of Ohio State on building resilience in the supply chain.

Resilience is an ability to adapt and having contingency in place to reduce potential disruptions.

Three Steps to Make a Business Case for Sustainability

Most companies know sustainability is important for future success, but few manage to make it an integral part of their business. To do so, it has to be worth it. Here are three steps to analyze the impact of going green:

- Take a close look at your supply chain. Collect baseline measurements on energy, material, and natural resource usage.

- Get a quick win. Select a pilot project based on your initial measurements that will produce concrete data quickly. For example, look at heating oil usage in one store and explore how to reduce it.

- Expand the initiative. Once you reach the small-scale goal, expand the project to other areas. Communicate the initial results and the company's goals for sustainability to the entire organization.

There are reasons why CEOs should be tapping their Head of Supply Chain to unlock these benefits, not their Head of Sustainability.

Taking waste out of the system while gaining strong brand experience is creating sustainable value.

Manage Your Risk In Turbulent Times and Meet Increased Demands For Sustainability

Sustainability is risk to most companies. There is a shift upward. Value creation is the new opportunity from it.

• Improved sourcing transparency is demanded by more customers and stakeholders

• Shift by companies is to take on the challenge and use sustainability as a differentiator

• Sustainable supply chain are evolving as source of value creation and competitive advantage

Sustainability (CSR) and risk drives the value chain.

Meeting Increase Demands For Sustainability -> Value Creation

Risk and sustainability are neither separate nor mutually exclusive or even stand alone elements.

The traditional approach was to deal with risk and sustainability in this manner. Actually, they are best worked as complementary to the same coin for gaining maximum value in the supply chains of the future. The linkage between risk and sustainability has gained traction recently through a number of studies and realizations socially. This is facilitated through a lens of better transparency brought on by new technologies and improved processes. There is a social contract that companies cannot afford to ignore and gains to be made in maximizing value for them. There is a heightened awareness that companies are to be seen taking action on social, environmental and economic issues. In addition, they are held accountable for reducing risk with improved sustainable products and services.

Transparency via improved process and new technologies are an enabler to take the complexity out of large global supply chains. This makes the connections with an extended depth of supplier’s supplier relationship management, while creating sustainable value. This alignment in outlook also leads to deeper relationships and engagement between the buyer and the supplier. It improves design, reduces risk and helps the company operate more sustainably.

Increase market share through Corporate Social Responsibility (CSR) engagement.

Best in Class and Scalable Structure

Scalable Organization Structures and Evolution

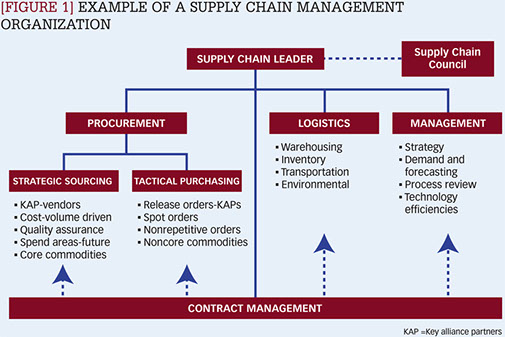

Below is a good example of a balance organization structure in Supply Chain Management. It’s scalable for the business.

Best in Class Supply Chain Organization:

Want to be a "best in class" organization? Then follow the lead of highly successful companies and adopt these 10 practices in your own operation.

- Establish a governing supply chain (SC) council- Note: Best results for organizations – have representatives on the SC council from across your Lines Of Business (LOBs) and Special Product Groups (SPGs)

- Properly align and staff the supply chain organization

- Make technology work for you

- Establish alliances with key suppliers

- Engage in collaborative strategic sourcing

- Focus on total cost of ownership, not price

- Put (all) contracts under the supply chain function

- Optimize company-owned inventory

- Establish appropriate levels of control and minimize risk

- Take green initiatives and social responsibility seriously

[Figure 1] Example of a supply chain management organization

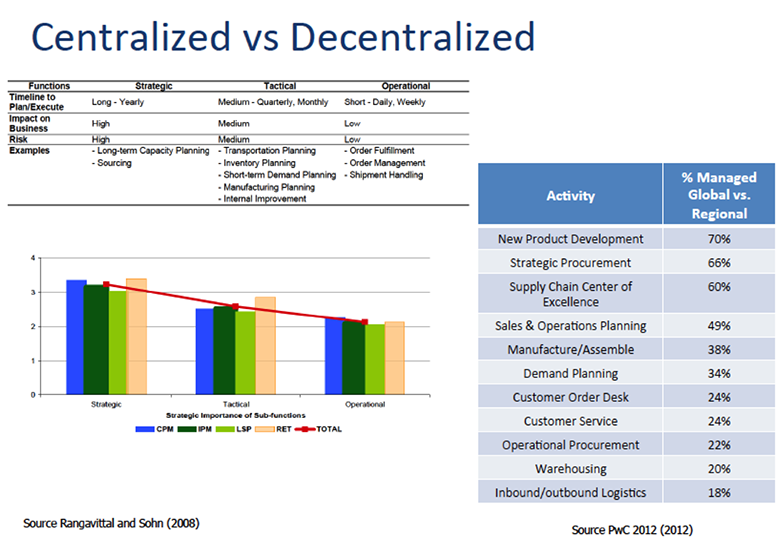

MIT’s slide above and points below regarding Organization Design and Trade-Offs to be consider:

1. Strategic vs. Operational Coordination

i. Where in organizational Hierarchy does supply chain belong?

ii. Is it a peer to Operations, Manufacturing, Sales, etc..?

2. Line vs. Staff Coordination

i. Where do line activities occur?

ii. Does supply chain activity occur in within all areas or only staffed in supply chain?

3. Centralized vs. Decentralized Coordination

i. Which activities are best administrated and controlled from a central (headquarters) location?

ii. Which activities are best administrated and controlled from decentralized (regional) locations?

iii. How is coordination made between regions, countries, business units (BUs), channels, divisions, etc.?

Having the right people, good processes and best technology for scalable and improved business.

Key is finding balances and trade-offs between the three.

Achieving Optimization

World Wide Network Case Study Example - Configuration For Global Distribution

- Map of world wide network with distribution centers (DCs), customer demand by regions and manufacturing plants locations:

- Supply chain optimization and structure alignment for global distribution uses an application method of processes and tools. The supply chain design method tests and ensures the optimal operation of a manufacturing and distribution supply chain. This includes the optimal placement of inventory within the supply chain, minimizing operating costs (including manufacturing costs, transportation costs, and distribution costs). This often involves the application of mathematical modeling techniques using computer software. Plus the supply chain modeling is a useful way to perform sensitivity analysis on the network design to get the gains mentioned below.

Case study - world wide network configuration and optimized for global distribution

Steps taken:

- Determine the strategy

- Identify the current network structure

- Tested various scenarios for global distribution and structure alignment

Outcomes and results:

- Increased ownership by regional sales for customer delivery and fulfillment

- Reduced the overall network cost and number of stocking points

- Gained real estate reduction and asset consolidation

- Consolidate buying power and reduce number of 3PLs

- Centralized distribution- European, North American and Asian Models

- Direct delivery – major customers- increased response rate

- Obtained balance of cost to service-optimize network

- Target – exceed 10% savings. Achieved 27%- + 15% order cycle improvement

Supply Chain Modeling is a useful way to do sensitivity analysis on network redesign to get these gains.

Supply Chain Design - Method for Network Configuration for Optimal Supply Chain Solutions

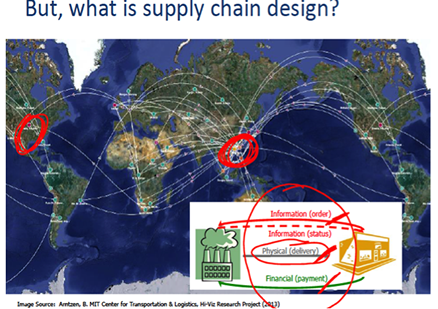

Major Universities, such as Massachusetts Institute of Technology (MIT)‘s slide below, are now emphasizing the use of Supply Chain Design. It is to determine best network configuration for optimal supply chain solutions though a number of scenario’s modeled and tested before implementing the changes.

Supply Chain Design is made up of three (3) major flows as circled in the MIT’s slide above and noted:

- Information flows for orders and status

- Physical flows form source to customer and returns

- Financial flows between buyers and sellers

Note - Inventory models involve relationships that are not easily represented in optimization models. Practitioners who develop supply chain models harbor an “open secret” about this modeling incompatibility that is rarely revealed to the managers who are their clients” Jeremy F. Shapiro (2007) Modeling the Supply Chain (2nd. edition)

DCI STRATEGIC © ALL RIGHTS RESERVED.