OPTIMIZATION

World Wide Network Case Study Example - Configuration For Global Distribution

- Map of world wide network with distribution centers (DCs), customer demand by regions and manufacturing plants locations:

- Supply chain optimization and structure alignment for global distribution uses an application method of processes and tools. The supply chain design method tests and ensures the optimal operation of a manufacturing and distribution supply chain. This includes the optimal placement of inventory within the supply chain, minimizing operating costs (including manufacturing costs, transportation costs, and distribution costs). This often involves the application of mathematical modeling techniques using computer software. Plus the supply chain modeling is a useful way to perform sensitivity analysis on the network design to get the gains mentioned below.

Case study - world wide network configuration and optimized for global distribution

Steps taken:

- Determine the strategy

- Identify the current network structure

- Tested various scenarios for global distribution and structure alignment

Outcomes and results:

- Increased ownership by regional sales for customer delivery and fulfillment

- Reduced the overall network cost and number of stocking points

- Gained real estate reduction and asset consolidation

- Consolidate buying power and reduce number of 3PLs

- Centralized distribution- European, North American and Asian Models

- Direct delivery – major customers- increased response rate

- Obtained balance of cost to service-optimize network

- Target – exceed 10% savings. Achieved 27%- + 15% order cycle improvement

Supply Chain Modeling is a useful way to do sensitivity analysis on network redesign to get these gains.

Supply Chain Design - Method for Network Configuration for Optimal Supply Chain Solutions

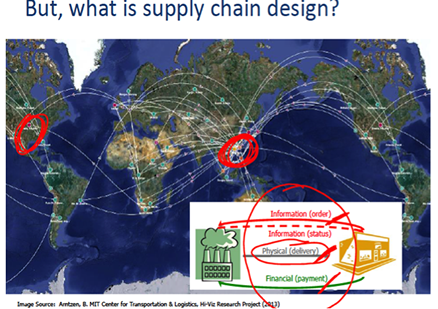

Major Universities, such as Massachusetts Institute of Technology (MIT)‘s slide below, are now emphasizing the use of Supply Chain Design. It is to determine best network configuration for optimal supply chain solutions though a number of scenario’s modeled and tested before implementing the changes.

Supply Chain Design is made up of three (3) major flows as circled in the MIT’s slide above and noted:

- Information flows for orders and status

- Physical flows form source to customer and returns

- Financial flows between buyers and sellers

Note - Inventory models involve relationships that are not easily represented in optimization models. Practitioners who develop supply chain models harbor an “open secret” about this modeling incompatibility that is rarely revealed to the managers who are their clients” Jeremy F. Shapiro (2007) Modeling the Supply Chain (2nd. edition)

DCI STRATEGIC © ALL RIGHTS RESERVED.